DELTA Damping Systems

How it Works

How it Works

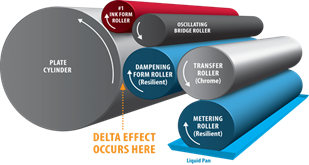

The unique Delta design utilizes helical gears and positive roller settings to drive the dampening form roller at a slower surface speed than the plate cylinder. The differential motion, called the “Delta Effect” wipes away the foreign particles that cause hickeys, while continuously allowing a fresh charge of ink to the plate.

Features

- Delta Dampening System retrofits are available for virtually every major press model

- Form roller operates at a lower surface speed than that of the plate

- Dampening form roller is separate from the inking system, allowing for the retention of all ink form rollers

- Separate variable-speed drive motor and water control adjustments

- Thin film of precisely metered dampening solution is applied as required across the plate

- Exclusive Epic air-activated oscillating bridge roller reduces ghosting

- Instantaneous control of ink/water balance

Benefits

- Guaranteed hickey-free printing — eliminates downtime, metal waste and sorting time

- Smoother, denser solids

- Sharper halftones with less dot gain

- Cleaner, sharper reverses

- Sharper, dryer print

- Tighter screens without plugging

- Excellent color control and consistency

- Faster make-readies

- Increased operator safety

- Overall cost savings – reduced waste and ink usage, improved press efficiencies

- Rapid return on investment